Yankee Hoods and Air Systems

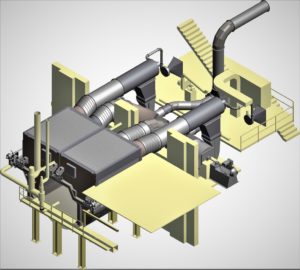

The Yankee Hood is a highly specialized piece of equipment that uses very high temperature air for high-speed drying primarily of tissue and towel products. A machine mounted Yankee Hood, combined with an air movement and heating apparatus located behind the machine, makes for a high efficiency and fuel economic drying system.

AIRTHERM Yankee Hood AER Systems span the entire range of application requirements from low-speed and low temperature to high performance systems for high-speed machines. AIRTHERM’s exclusive nozzle design can yield high heat transfer performance and efficient hood balance with reduced fuel requirements. Using proprietary computer generated analysis software, AIRTHERM can document and guarantee thermal efficiency.

With over 50 years experience in tissue and towel drying, AIRTHERM provides Yankee Hood AER Systems with high drying rates and energy efficiency.

Features:

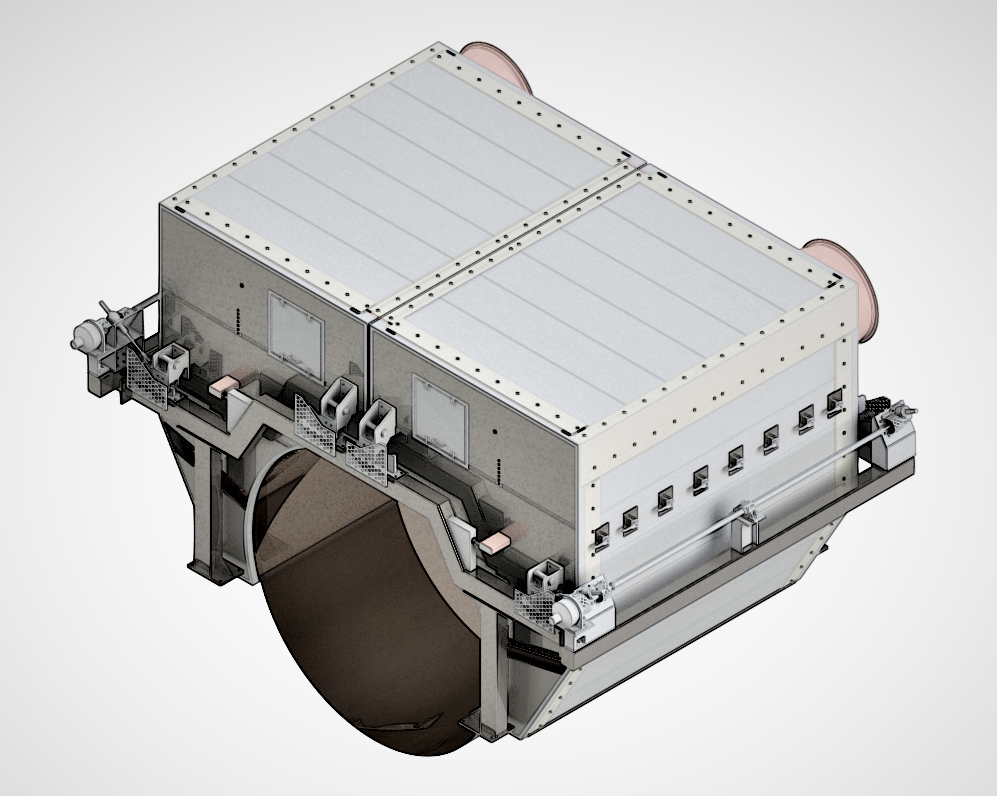

- Our Yankee AER Hood supply plenum uses a uniquely designed supply air distribution plenum which features an array of round impingement orifices sized and spaced for ideal heat transfer.

- Single or dual air speed and temperature controls with standard edge dampers and optional cross-machine profiling.

- Special stainless steel grades available for more durable construction and corrosion resistance.

- Stainless steel-clad support steel eliminates corrosion and never needs painting.

- Hood retraction using motorized screw jacks or air cylinders.

- Fabric or stainless steel flexible duct sections tied into the supply and recirculation duct runs allow the AER cap to retract without the ducts separating.

- Rapid temperature rise fans with water-cooled bearings and cantilevered or center-supported wheels.

- Wide variety of air heaters including several burner packages for efficient, low emission operation.

- A dynamic air seal to prevent hot air from spilling out of the hood.

- Pre-assembly of the Yankee Hood on the support steel before shipment to insure the proper fit.

- Sizing programs designed to analyze and predict upgrade benefits. Our AER Cap Thermal Expansion Program analyzes the size, weight and operating temperature to find the ideal position of the structural support stops and wheels. This analysis eliminates clearance changes due to thermal expansion.

- Heat Recovery systems to capture excess heat exhaust from the AER system.

- Repairs, Upgrades & Spare Parts are available on existing systems regardless of the original manufacturer.